Sinter-based additive manufacturing technologies

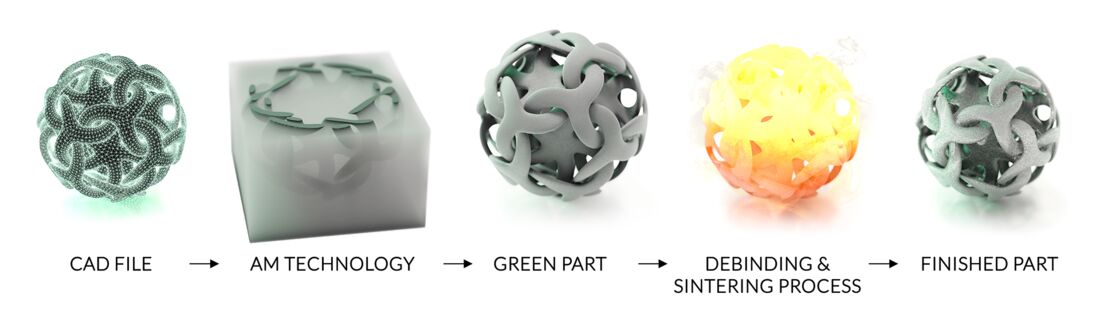

Additive manufacturing technologies can be divided into two categories, direct and indirect. The last is also known as sinter-based additive manufacturing and involves a two-step process. During this process, a green part is first printed using a sinter-based additive manufacturing technology, followed by debinding and sintering.

Advantages of sinter-based additive manufacturing are the high productivity and the fact that no support structures are needed, which strongly influences the surface quality of a component and reduces costly post-processing. In addition, the component properties achieved are comparable to the established MIM technology.

LMM

Lithography-based Metal Manufacturing

LMM technology enables the production of high-precision small and micro metal components. It is best suited for applications up to 2 cm in length, width and height. The technology can achieve a very smooth surface with an Ra of 2 μm without post-processing as well as tolerances up to ± 0.05 mm (± 0.5 %).