Sinter-based additive manufacturing enables a wide range of new applications

3D printing is meanwhile known in almost every industry and is used in particular for prototypes. However, series applications can also be implemented with indirect additive technologies such as LMM technology. From medical technology to metal processing and mechanical and plant engineering to the luxury industry and jewelry, there are a large number of applications whose production can be economically implemented with sinter-based processes.

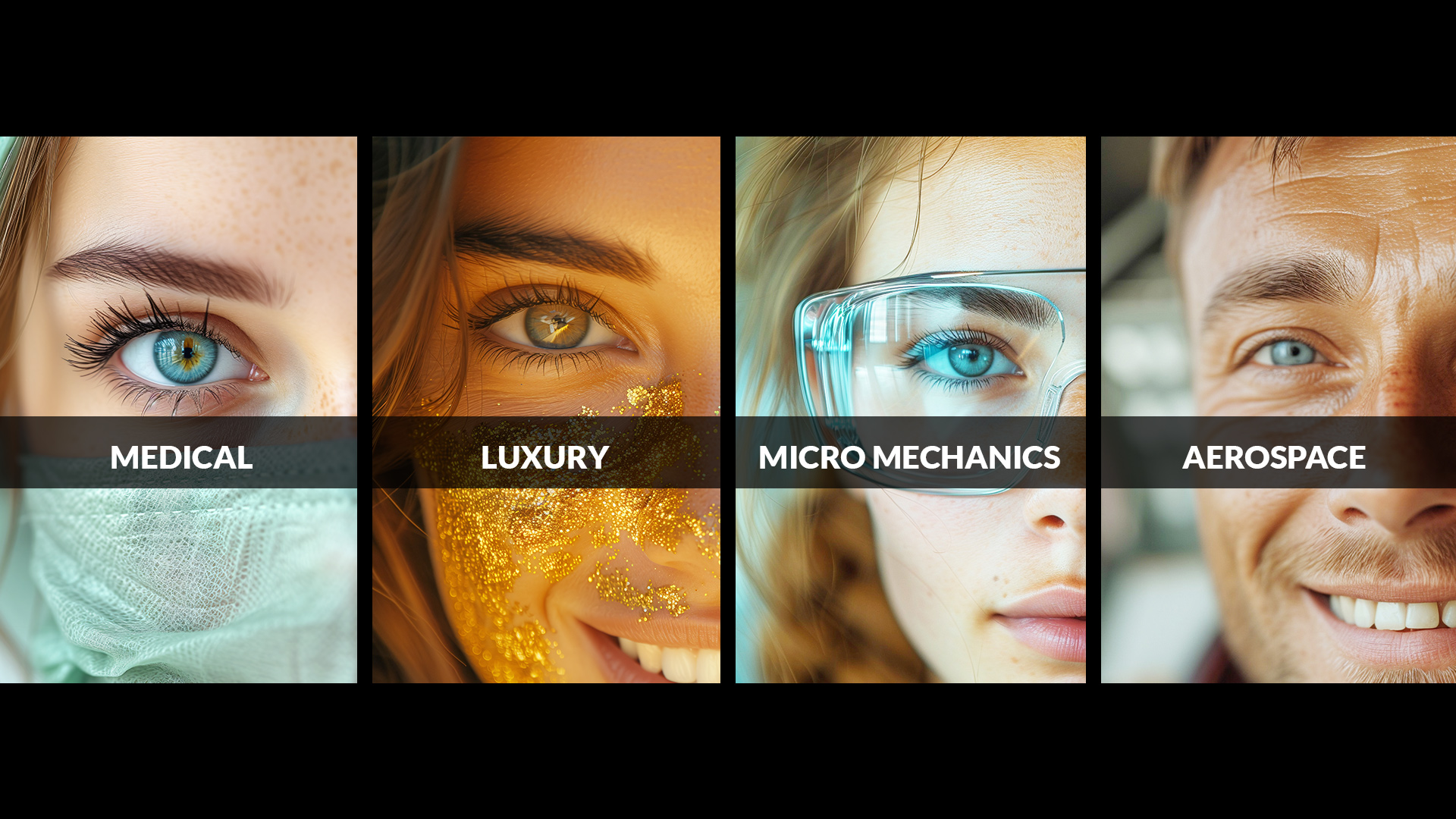

Medical Technology

The medical technology industry was one of the first industries to implement additive manufacturing and in the beginning, it was mainly used for the manufacturing of complex prototypes. In the meantime, additive manufacturing is also used for the production of applications such as prostheses, orthoses and surgical instruments. Especially short production times, cost reduction and material efficiency are convincing factors when focusing on additive manufacturing technologies. Another special field of application is the production of special instruments and implants, which are individually tailored to individual patients. Particularly in medical technology, high quality of the finished product is indispensable, which means that high standards in the area of materials and surface finishes are necessary, which can only be offered by a few 3D printing service providers.

Mechanical Engineering

Additive manufacturing provides the mechanical engineering and metal processing industry with an economical alternative to traditional manufacturing processes. When manufacturing complex components, especially those made of expensive materials and/or with high material removal, companies benefit from the high material efficiency and design freedom of additive processes. The production times for prototypes and pilot series, which are reduced to a minimum, are particularly positive for development. Individual parts or small series, such as spare parts in small quantities, can also be produced much more economically. Additive manufacturing offers a fast and efficient solution for the production of complex components for which individual tools or moulds have to be developed at great expense or which require frequent tool changes.

Luxury & Jewellery

Additive manufacturing is not only suitable for the production of presentation models of a new design, but also for the actual production of earrings, rings, pendants, cufflinks, etc. With additive manufacturing the production of a new design can begin immediately after the design has been completed making it possible to react quickly to new trends. Printing jewellery and other luxury goods using CAD files proves to be extremely accurate in practice. Moreover, additive manufacturing positively influences the degree of complexity and individuality. The creative freedom of designers and customers is no longer limited, so unique pieces can be designed and/or customised.

Your application is from an industry not mentioned? Expand our horizons and yours with your application!