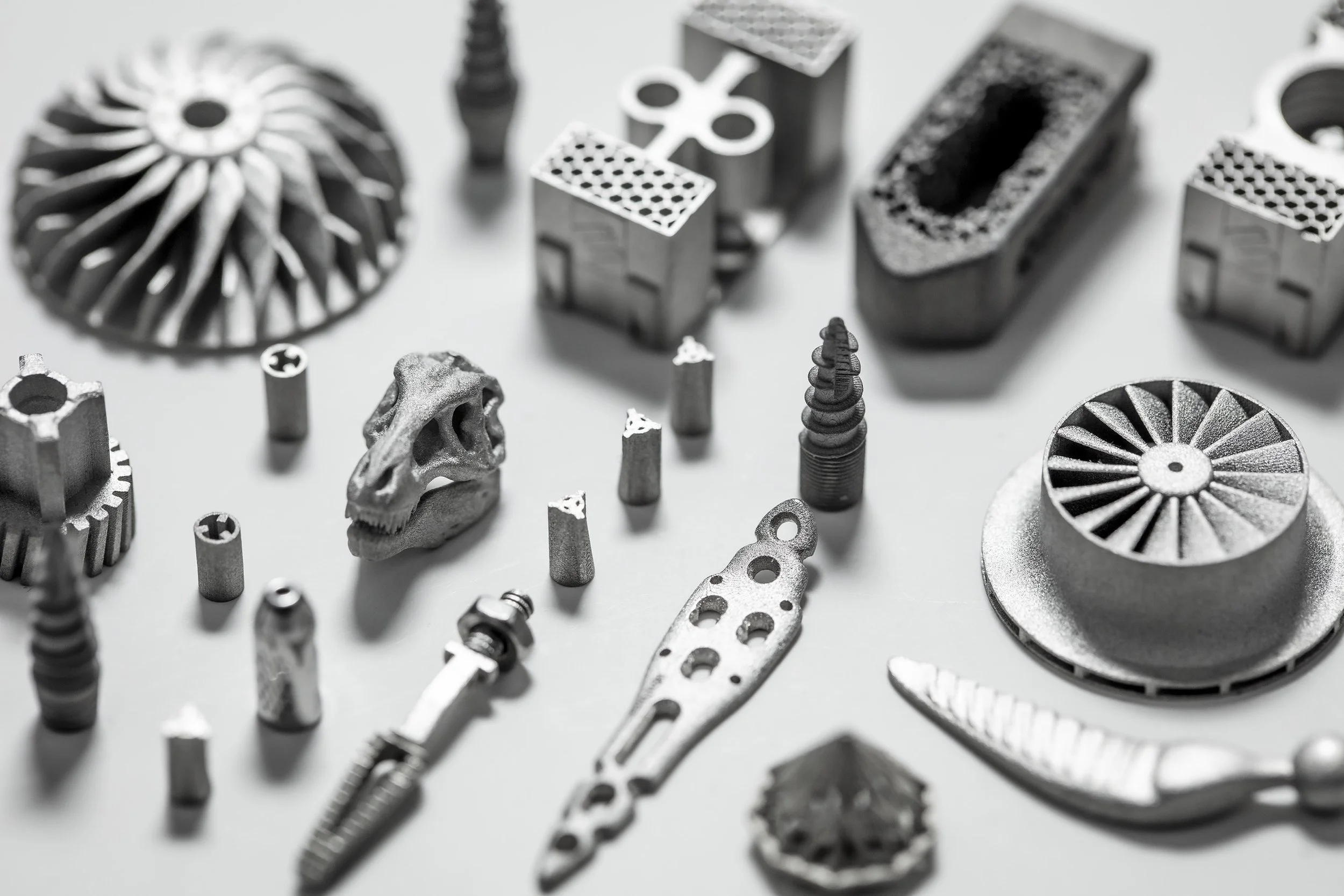

Empowering your switch to additive manufacturing for micro metal parts

Fast prototyping iterations accelerate your product development

Single-step manufacturing of complex geometries with no tooling required

Switch to additive manufacturing and reduce your cost per part

Our Services

Product Development

Considering additive manufacturing for micro metal parts?

We bring full expertise in design optimization, part testing, and technology validation — helping you innovate and get the most out of LMM to assess whether it’s the right fit for production.

-

Conventional manufacturing for micro metal parts often requires expensive tooling and long wait times before first parts are ready. With LMM, tooling is no longer needed, which saves both cost and time. You can move from design to first parts in days, not months — making your development cycles far more efficient and flexible.

-

Speed is critical when exploring new designs. With our LMM technology, you can iterate quickly, test multiple variations, and refine your design with parts delivered in as little as 1–2 weeks. This means faster learning cycles, earlier validation, and quicker progress toward production readiness.

-

Additive manufacturing allows you to go beyond the limitations of conventional production — enabling new geometries, integrated features, and single-step manufacturing instead of multi-step processes. We help you leverage these advantages to innovate, optimize, and validate your part design, ensuring it is both functional and ready for production.

Manufacturing at Scale

Ready to scale micro metal parts?

We offer flexible LMM manufacturing. From low-volume ramp-up to full production. Robust quality control ensures consistent, repeatable results, delivering reliable, ready-to-use micro metal parts.

-

Whether you need tens, hundreds, or thousands of micro metal parts, our LMM manufacturing adapts seamlessly to your production volume. Single-step manufacturing allows complex micro geometries at low cost, as no multi-step process is required. You can scale up or down without changing processes or compromising quality, ensuring flexibility to meet market demand.

-

From design handoff to finished parts, we manage the entire manufacturing process with strict quality control. Every stage is monitored to guarantee consistent, reliable results, so you can trust that your micro metal parts will perform as intended.

-

Our streamlined LMM process delivers parts quickly while maintaining high precision and tight tolerances. This allows you to meet project deadlines and accelerate production cycles without sacrificing the quality or performance of your components.

Micro Metal Parts

LMM: Lithography-based Metal Manufacturing

LMM stands for Lithography-based Metal Manufacturing. It’s an advanced sinter-based additive manufacturing technology used to produce high-accuracy micro metal parts.

As experts in sinter-based additive manufacturing, we master the LMM process to produce high-accuracy micro metal parts. From development to series production, we deliver ready-to-use components with exceptional quality and efficiency.

With the ability to print complex geometries in a single step and no need for tooling, we enable rapid prototyping and fast design iterations—accelerating your product development and helping you perfect your parts.

After robust testing and validation, we seamlessly scale to full production, giving you the flexibility to ramp up and manufacture at scale.

Explore

-

Our Services

-

Applications

-

Knowledge and Insights

Get in touch.

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, the way you tell your story online can make all the difference.